Recently, I discovered a workshop in Brussels that offers hands-on experience in disassembling and reassembling watch movements. From what I’ve gathered online, they hold these events once a month. The workshop starts with welcome snacks and drinks, followed by a presentation on watch movements and tools, and wraps up with more refreshments. The whole experience costs 350 EUR. You also get the chance to buy some of the tools used in the workshop, meet fellow watch enthusiasts, and wear a traditional watchmaker’s coat. Whether this three-hour session is worth the price is hard to say. For me, the real draw wouldn’t be the watch movement activity itself but the opportunity to network with other horology lovers.

I don’t need a 350 EUR workshop to take apart and reassemble a watch movement—I can do that in my own workshop with my own tools. Sure, I don’t own a watchmaker’s coat, but that’s just a few clicks away on Amazon. What would be more unique is sitting at a watchmaker’s bench, which is a bit harder to come by and comes with a much heftier price tag of around a thousand euros.

As you might recall, I recently completed my first watch movement disassembly and reassembly using tools I bought for my birthday. They’re good tools, but I quickly realized there was room for improvement. For instance, I needed a better watchmaker’s loupe and a loupe wire. The two loupes that came in my kit were decent, but not great. And, without a wire, it’s extremely difficult to keep the loupe steady on your eye.

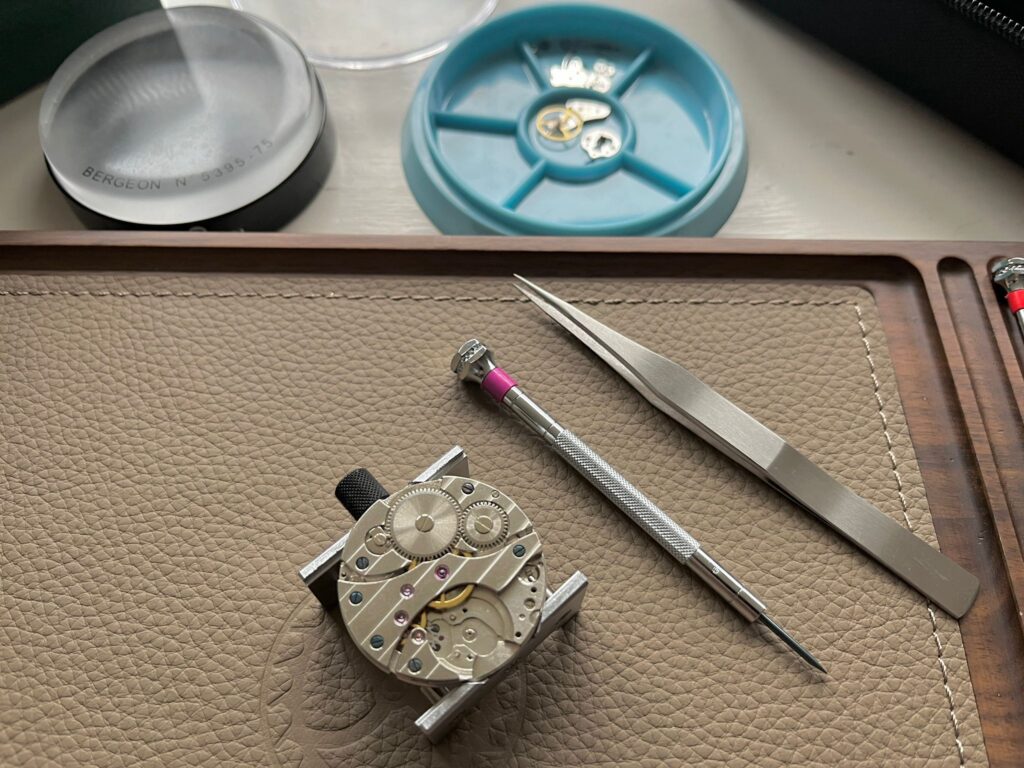

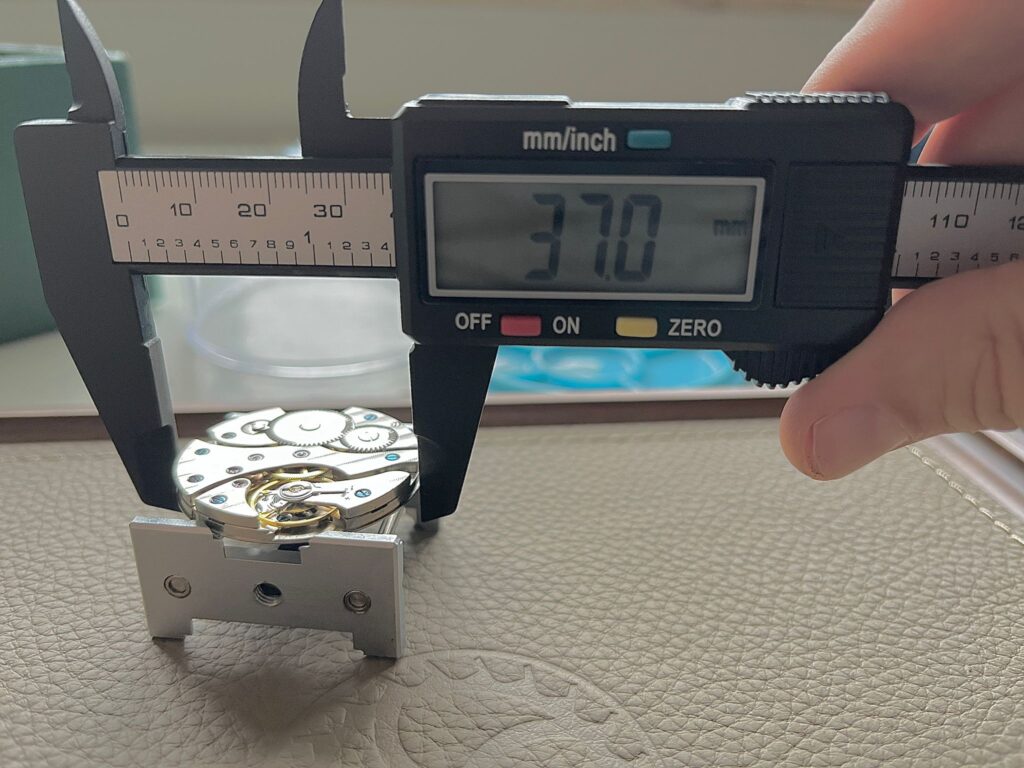

Another issue was the movement holder—it wasn’t strong enough to secure a 37mm movement. Thankfully, Bergeon makes a fantastic steel movement holder, and the difference in quality is immediately noticeable. It holds a 37mm movement perfectly. To complement that, I also purchased a watch cushion, which has a gel surface to prevent parts from slipping or bouncing while working on the dial side of a movement. I also picked up a Bergeon case back opener, though I haven’t had the chance to try it yet. I acquired something else, but that will remain a mystery for now. I need to build up more confidence and skill before I tackle that project.

Circling back to the workshop, one detail I noticed from photos of past events was the use of dustproof component covers. My toolkit included one, but I skipped it during my first attempt, opting instead to arrange all the parts directly on my mat. But if someone is paying 350 EUR to use these covers, I might as well use mine in my own workshop. During my next disassembly, I made an effort to use the cover to protect the parts from dust and other elements. Unfortunately, I didn’t do as well during the reassembly—leaving the cover off the entire time—so it’s safe to assume some dust may have settled on the movement. I’ll be more mindful during my next attempt this weekend.

My second disassembly went smoothly, following the same steps as before, and I was done in about 10 minutes. This time, I used my new loupe and kept the parts organized on a tray. Had I followed my original approach of using only the mat and my unaided vision, I might have finished even faster.

Reassembly, however, hit a snag when I reached the gear train. While I knew where the escape wheel and the large center wheel belonged, I mixed up the seconds wheel and the intermediary wheel. It took about 10-15 minutes and a bit of Googling to get them in the right order. At least now I’ll never forget the sequence.

This weekend, I plan to disassemble and reassemble the movement again, maybe even twice, to build more experience and confidence. My next project is a bit more intricate and smaller in size, so I want to be fully prepared. Ultimately, my goal is to get my hands on a broken Rolex or Omega and restore it to working condition.

This hobby has completely captivated me. My wife often reminds me that I’ve yet to read Watchmaking by George Daniels—the Bible of horology. I actually brought the book with me to Brussels. Four years ago, my wonderful wife gave it to me as a gift, and now, unlike back then, I’m actually practicing watchmaking. While I’m not building a watch from scratch, I’m certainly doing more than just setting the time, winding a watch, or admiring beautiful pictures.

I haven’t decided whether I’ll write a short article after every watch movement disassembly and reassembly, but stay tuned for my second movement. Unfortunately, it’s not a Rolex. Yet.

Kindly,

Olaaf